By Robert Armbrester, P.E., CEM, LEED A.P.

As the SARS-CoV-2 pandemic enveloped the U.S. in March 2020, the need to mitigate the transmission of this airborne pathogen became evident. In response, the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) developed a position paper addressing infectious aerosol transmission and highlighting the role of HVAC systems and controls in decreasing the propagation of these particles.

Unfortunately, equipment and infrastructure funding available to replace or modify existing equipment has always been limited. These budget constraints, now more than ever, emphasize the importance of targeted asset management strategies across the military’s facilities nationwide and around the globe.

In isolation, HVAC systems are unable to completely inhibit the distribution of these pathogens, as the efficacy with which these systems can address such risks is dependent upon such factors as the concentration, source, particle size, and mode of transmission of these contaminants. Nonetheless, building science professionals understand that there are highly practical approaches by which HVAC systems can significantly reduce potential distribution of such airborne illnesses. These methods typically involve equipment upgrades or system modifications, both of which require some level of asset management and prioritization.

ASHRAE strategies

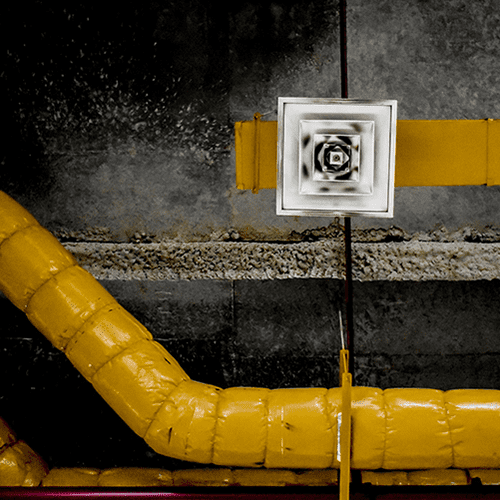

ASHRAE has highlighted the following strategies to initially address the on-going pandemic: air distribution patterns, dilution-based ventilation, space pressure differentials, filtration, and regulation of space temperature and humidity. In most cases, the facility management team will utilize a combination of these strategies, the selection of which should be carefully assessed against available resources, existing conditions, and design considerations.

One of the more prevalent means by which to reduce the build-up of infectious particles is to introduce more outside air into the facility, an approach that can include changing the setpoint of the outside air damper for each air-handling unit and disabling any demand control ventilation. Ideally, 100 percent outside air would be brought into the building to avoid recirculation of air.

However, this tactic requires additional energy to heat/cool the incoming air, to maintain acceptable temperature and humidity setpoints. In many cases, the existing HVAC equipment will not have sufficient capacity to properly condition the additional ventilation air. In these scenarios, outside air dampers should be set to the maximize ventilation without sacrificing proper humidity and temperature control.

Due to the energy penalty associated with additional outside air tempering, the effective implementation of heat recovery needs to be considered. There are multiple approaches to reclaiming the energy from exhaust air, such as rotary thermal wheels, fixed-plate heat exchangers, heat pipes, and run-around coils. Each of these options have inherent pros and cons that must be critically assessed in accordance with facility occupancy and operations.

Heat recovery tactics

The most common type of rotary thermal wheel employs the use of a wheel that is coated with some form of desiccant material that permits the exchange of both sensible and latent energy between the two air streams. When the indoor environment requires heating, the exhaust air acts to both pre-heat and humidify the incoming outside air. Conversely, when the facility is in cooling mode, the exhaust air serves to pre-cool and dehumidify outside air.

The primary advantage of the desiccant wheel is the capability to recover both sensible and latent forms of energy. The main drawbacks to these systems include the cross-contamination potential between air streams, the requirement for adjacent air streams, and the energy input required to rotate the wheel and recharge the desiccant material.

Equipment asset management is more important than ever for facilities around the globe fighting the transmission of airborne pathogens.

Heat pipes offer another option to optimize the efficiency of an HVAC system.

Enhanced air filtration of occupied areas impacts transmission of airborne illnesses.

Fixed-plate heat exchange

Fixed-plate heat exchange involves the transfer of sensible energy between two air streams passing through passages formed by fixed plates of highly conductive material. These exchangers are the most common form of heat recovery and have been in use for over 40 years.

Chief advantages of this heat recovery application include no cross-contamination potential, no moving parts, and high transfer efficiencies. Hindrances include significant pressure drop across the plates and condensation accumulation within the exchanger.

Heat pipes

Heat pipes offer another option to optimize the efficiency of an HVAC system. They use a working fluid that undergoes a phase change around the same temperatures that are experienced within a typical air-handling unit or other cooling system configuration. Warm, outside air releases some of its sensible heat to the working fluid, causing the fluid to evaporate and travel towards the other end of the tube or wicking capsule.

Due to this heat loss from the outside air, the heat pipe has served to pre-cool the air before it flows across the cooling coil(s). This second stage of cooling allows even more moisture to condense out from the air stream. Now the air is slightly over-cooled as it passes across the other end of the heat pipe, where the working vapor releases its sensible heat back to the air stream, as a form of reheat, before the air is distributed to the space.

The increase in efficiency results from the pre-cooling effect of the heat pipe before the air crosses the primary cooling coil(s), so less mechanical energy is required to deliver the same amount of cooling. Additionally, since the air leaving the air-handling unit has an even lower relative humidity, this air can be supplied to the space at slightly higher temperatures. This same effect is similarly available for heating applications. Some of the advantages associated with heat pipe technology include no moving parts, low pressure drop, and no cross-contamination potential. The disadvantages include a larger mechanical casing required to incorporate the heat pipe configuration and comparably lower efficiencies relative to other technologies.

Run-around coils

Run-around coils offer another opportunity to transfer heat from one air stream to another. In this application, hydronic coils indirectly interface with the outside air and exhaust air. In cooling mode, the relatively cool exhaust air absorbs heat from the hydronic coil, allowing the hydronic fluid to pre-cool the ventilation air.

In heating mode, the hydronic coil absorbs heat from the relatively warm exhaust air and delivers this energy to the outside air as a form of pre-heating. The working fluid in the hydronic coils is typically a mixture of water and glycol, depending on the climate where the facility is located. With run-around coil systems, the airstreams can be relatively distant from each other and there is no cross-contamination potential. Shortcomings with this application include relatively low efficiencies and a significant pump energy requirement to circulate the working fluid.

The heat recovery techniques mentioned above are highlighted since most facility managers will primarily use dilution ventilation to mitigate the transmission of aerosol contaminants. ASHRAE, however, recommends that multiple measures be taken to curtail the dissemination of these pathogens.

Pressure cascading & enhanced filtration

A practice often encountered in healthcare facilities and clean room environments is space pressure cascading, where more supply air is delivered to a space relative to adjacent areas. This airflow disparity creates a pressure differential between adjacent spaces, controlling the movement of toxins within the facility.

Pressure cascading typically involves additional exhaust air requirements to maintain a negative pressure environment, so the heat recovery modalities listed above should be exercised to improve operational efficiencies.

Enhanced filtration of the air delivered to the occupied areas is also highly effective in removing potential contaminants. ASHRAE recommends the installation of Minimum Efficiency Reporting Values or MERV-13 (or higher) filters within air distribution systems wherever possible. The increased MERV rating will result in a higher static pressure drop across the filter panel, so it is important to ensure that the supply/return fan has the capacity to overcome this additional pressure loss. The seals and gaskets around the filter media should also be inspected and maintained for operational integrity. If it is not feasible to increase the system’s MERV filter rating, then portable air purifiers are an alternate solution.

Humidity control

Lastly, the concept of humidity control within conditioned spaces is worth consideration, since it has been found that humidity levels ranging from 40% to 60% provide the most unfavorable conditions for microorganisms. Humidity control might require additional HVAC equipment and sensors to achieve. For example, in colder, dry climates, the installation of localized humidifiers might be required to increase space humidity. Supply air temperature reset strategies, that increase the supply air temperature, might need to be disabled to reduce humidity levels. Hot water reheat will need to remain enabled, to permit VAV reheat and humidity regulation. Humidistats will also need to be installed to control the existing or new equipment to maintain the desired humidity set points.

In conclusion

Although these strategies alone will not fully protect our armed forces and civil servants from the risk of exposure, they offer practical steps by which to minimize the threat of airborne transmission. Furthermore, most of the tactics listed here can be achieved through relatively minor and inexpensive modifications to existing equipment, thereby reserving maintenance capital for long-term equipment acquisition and calculated asset management objectives.