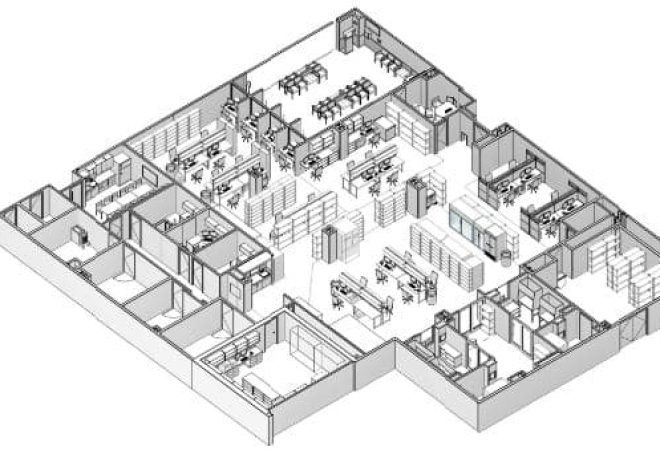

VA Houston Upgrade Sterile Processing Service (SPS)

Apogee was tasked with providing full and complete design drawings for the renovation of the Sterile Processing Supply (SPS) Suite located in the basement level of the Michael E. DeBakey VA Medical Center.